Core Advantages

Xinzhu Corporation cooperated with Dortmund H-Bahn21 to introduce the complete system of H-Bahn suspended monorail.

The system, a light weight, medium and low passenger capacity rail transit system with mature technology, has been operated safely in Germany for 36 years.

With small marshalling, high density of dispatching as well as thin beams and columns, the system operates automatically. The beams and columns are light, and can be prefabricated in factory, which makes its construction period very short. It is well-adapted to different climates and environments with low maintenance costs. This system could be used as supplementary lines to main lines in a megapolis and a metropolis, used in tourism transport or transport in special regions.

ADVANTAGES OF SUSPENDED MONORAIL SYSTEM

Safe and reliable operations

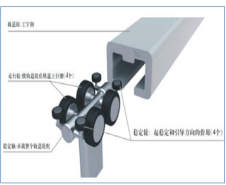

The bogie of the vehicle is placed in a semi-closed track beam with a lower opening, and the running wheels will not derail, preventing the possibility of safety accidents such as rollover of the car body. The suspension device between the car body and the bogie adopts a redundant design.

Line adaptability

The running wheels are rubber wheels. The running surface of the track beam is increased by grinding and spraying. The minimum plane curve radius that the bogie can pass is 30 m. The ability to adapt to terrain and surrounding environment is significantly enhanced, which can effectively reduce the amount of engineering And demolition volume.

Environment friendly

The running surface is not open-air, and it is not affected by severe weather such as freezing rain and snow. It can run all weather. The running wheel uses rubber wheels and the semi-closed track beam structure makes the running noise less. The noise is 6.5 m away from the center of the line. The value is about 65dB, which is much smaller than the steel wheel and rail system. The width of the pier is generally less than 1m, the structure is slender, and it occupies less ground resources. It can be conveniently installed on the ground location such as green belts and sidewalks. Recycling features can be extended or rerouted or demolished as the city develops.

Short construction cycle

A large number of steel structures are used. Except for the pile foundation that needs to be cast on site, all other structures are prefabricated in the factory, and the construction time on site is small. .

Good viewing effect

With the passengers standing high, the field of vision is transparent and unobstructed. With the design of a large-area transparent car body, a 360 ° viewing effect can be achieved.

Technology Highlights

The running surface is not open-air, and it is not affected by severe weather such as freezing rain and snow. It can run all weather. The running wheel uses rubber wheels and the semi-closed track beam structure makes the running noise less. The noise is 6.5 m away from the center of the line. The value is about 65dB, which is much smaller than the steel wheel and rail system. The width of the pier is generally less than 1m, the structure is slender, and it occupies less ground resources. Recycling features can be extended or rerouted or demolished as the city develops.